Content

Introduction

Since we are still missing a dining table after our joint move, we decided to build a dining table ourselves. Desire is to buy as little as possible new materials. Therefore, we use only used wood that was provided to us and would otherwise have served only to burn or lie around for more years until Mother Nature would have decomposed it.

However, we would buy fasteners such as screws and angle plates new for durability and safety.

Since there was a scorching heat during the day (34 °C), we limited ourselves to sawing the individual parts to length for the time being. This was also a good opportunity to inaugurate our new cordless universal saw, which performed phenomenally.

Planning

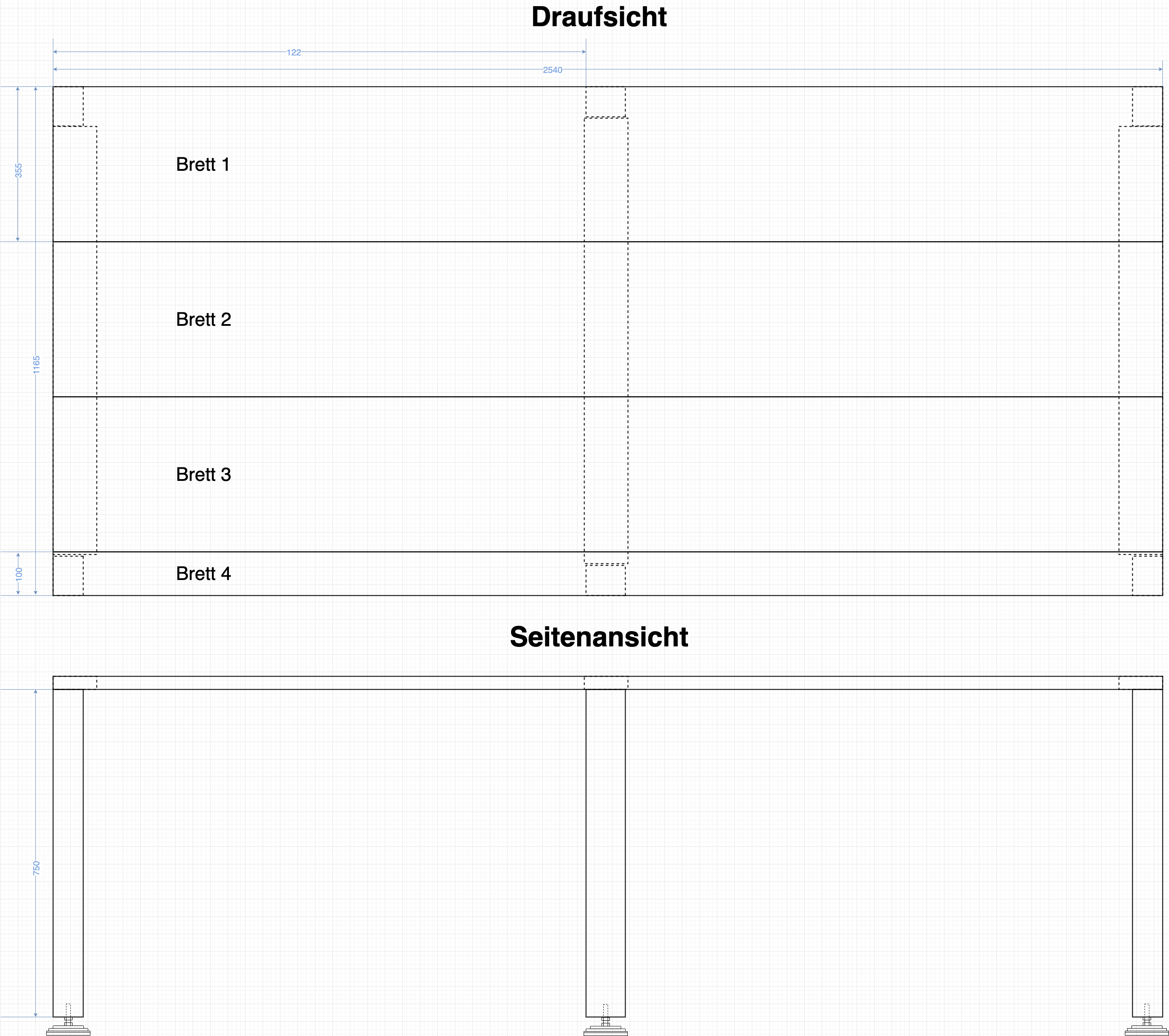

The drawing

I made the drawing after the woods were cut. The rough plan of what the table should look like was forged by Isabelle and I during the selection of the woods, depending on what was available. However, the drawing will serve as a reminder as I continue to work on the project so I still know which part goes where.

Wood choice

As mentioned at the beginning, we only made use of used building materials that had been lying around for years. For this purpose, we deliberately asked around in the immediate vicinity who had lumber that was no longer needed in order to use it for our project.

I am not an expert, so I can only make guesses about the type of wood and guess "oak wood". In my opinion, all the woods had too pronounced a yellowish tone for spruce wood and were sometimes quite firm when sawn. Also, all the woods did not have a lot of knots.

Since these are used woods, some of which have been lying for a few years, they are either a little deformed in places or have holes from old nails. However, this does not bother us, but contributes to the desired rustic style.

Working height

In our search for the right table height, we measured existing dining tables in our family environment and also used an online calculator. The Online calculator recommended a height of 71 to 74 cm for our heights. However, we found 70 cm to be a bit too low in the practical test, which was certainly also due to the chairs we sat on.

For this reason, we will provide the legs of the table with load feet, which can be adjusted via the thread.

The cutting

There's not much to say about the sawing itself, except that I needed a few cuts to get used to the new universal saw. Although I have often worked with jigsaws, the handling is initially different. After a bit of getting used to it, it didn't feel so different and was a lot of fun.

The "table top"

The table top consists of several individual boards. The three wide boards, each 35.5 cm wide, which are 2.54 m - 2.60 m long before machining, are decisive. We decided not to change the length significantly and only compensate for the marginal differences in length. Thus, we brought all the boards to 2.54 m and will thus have a massive dining table 😀. Since the table width would be a bit too much for us with four boards of this width, we added another narrow board to get to about 1.20 m wide.

Leave a Reply